Gas Odorization

40 Years of Experience Make LEWA Number One

Customers all over the world have been putting their trust in LEWA systems for more than 40 years when it comes to odorizing gas. Our portfolio of solutions for this application ranges from systems for micro-metering through to gas pressure regulation stations.

Scores of suppliers also put their trust in LEWA systems for odorizing LPG and CNG in the complete transport chain, as well as in gas stations and filling stations. Another large area of application for our systems is liquefied natural gas (LNG) in import/export terminals before distribution. And last but not least, LEWA odorizing systems are also used for odorizing oxygen and technical gases.

We plan and produce systems based on your specifications and, of course, equip them with LEWA core components: Pumps, flow meters, and a control system (closed control loop). Our systems use quantity-based odorization, controlled by the gas flow (injection process).

Areas of Application in Gas Odorization

LEWA odorizing systems allow you to add many different odorants to gases. This includes natural gas (1 bar to 300 bar), biogas (1 bar to 300 bar), LPG, oxygen, nitrogen, carbon dioxide, hydrogen, LNG, as well as unconventional gases.

| Areas of application for adding odor | Odorants | Customers |

|---|---|---|

| Natural gas in gas pressure regulation systems, transfer station (ÜRA)/City Gates, natural gas storage | THT, TBM, Gasodor S-Free | Public utility companies, trans-regional power suppliers, plant construction companies |

| LPG loading: Tank car, trucks, ships | EM | Refineries, oil and gas companies |

| Biogas plants | THT, TBM, Gasodor S-Free | Public utility companies, trans-regional power suppliers, plant construction companies |

| LNG Regasification (onshore, offshore) | ETHT, TBM, Gasodor S-Free | EPCs, plant construction companies, ship suppliers |

| Natural gas /vehicle gas filling stations | THT, TBM, Gasodor S-Free | Public utility companies, municipalities, energy utilities |

| Gas bottle filling (propane, butane) | EM | Gas bottle fillers |

| O2 odorization for oxygen distribution networks | DMS | Shipyards |

| Fire extinguishing systems (N2, CO2) | THT, TBM, Gasodor S-Free | General industry |

| Industrial bulk buyers of non-odorized gases | THT, TBM, Gasodor S-Free | Aluminum plants, glass factories, steel works, blast furnaces |

Advantages at a Glance

Modular design

You are free to choose: Standard odorizing systems are designed to be highly modular and consist of various components which enables us to meet your requirements in a manner that is as flexible as possible.

Customized units

Whatever your requirements are, we will find a solution: LEWA builds a complete customized system with standard modules or special components for you.

Microflow metering pumps

High metering accuracy: With our proven micro metering pumps (M and FC series), we guarantee accurate and reliable metering of the odorant.

Field-proven control and regulation systems

For smooth operation: Our systems have field-proven controls for hazardous areas. Connection to the Net-Port@l is possible.

Global commissioning

With our global service network, we take your equipment into operation and provide technical service directly at your location - both onshore and offshore.

Flexible design

You can rely on over 60 years of experience in the design of pumps, systems and units: During the project phase, we respond flexibly to design changes or adjustments required.

Maintenance and service

No matter if maintenance, spare parts or repair - our service technicians are well trained and available worldwide. Thus, we guarantee fast response and smooth operations.

Suitable for all odorants

LEWA odorizing systems are suitable for all common odorants in the industry: EM, DMS, TBM, THT. Simply let us know your personal requirements.

International standards

LEWA pumps, systems and units are compliant with major international standards such as DVGW G280, WHG, PED, ISO 9001, ASME, ATEX and TA-Luft. Of course, you can also define your own standards.

Reference Applications

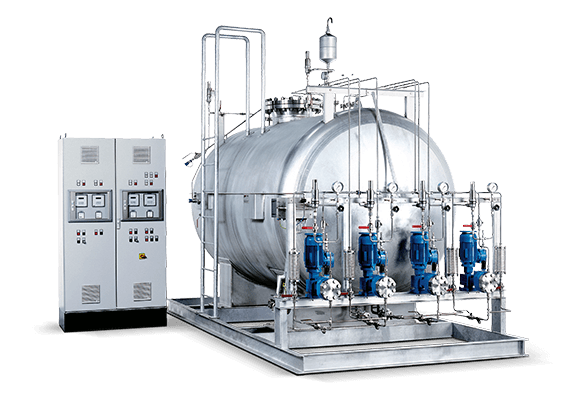

Gas odorization in the natural gas distribution grid

At hubs in the gas distribution network, big amounts of natural gas are forwarded. LEWA odorization unit OD 4200 is able to odorize gas amounts of up to 1.000.000 m³/h.

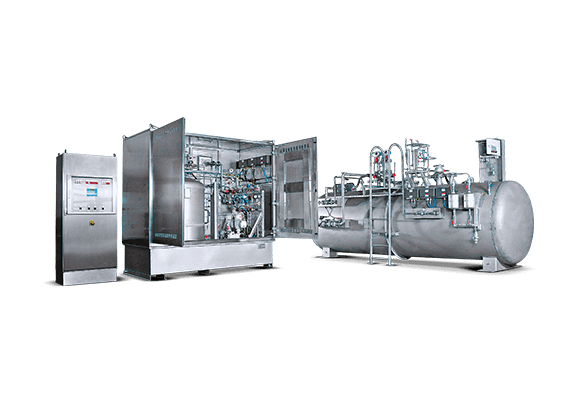

More DetailsBiogas odorization

The biogas odorizing systems from LEWA ensure a correct metering even with gas flow range of 150 Nm³/h with a gas pressure of up to 20 bar. Get in touch with our experts for your individual odorizing task!

More DetailsFurther Applications

Gas odorization with LEWA pumps and metering packages can be found also in many more applications:

- Micro-metering

- Odorization of LPG in the transport chain, in gas stations, and filling stations

- Odorization of LNG in import/export terminals before distribution

- Odorization of CNG at gas stations

- Odorization of oxygen and technical gases

Products

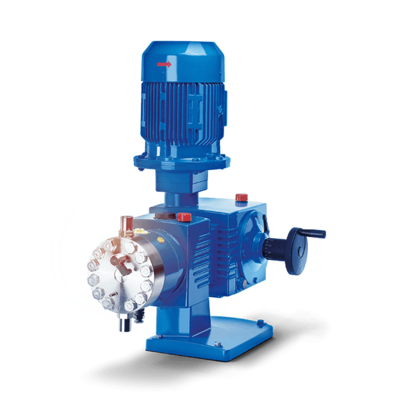

LEWA ecoflow® diaphragm metering pump

LEWA ecoflow is the innovative and universal metering pump with DPS diaphragm protection system in a tried-and-tested modular system. Suitable for numerous applications, the ecoflow is our real all-around talent, relied on by customers from all industries.

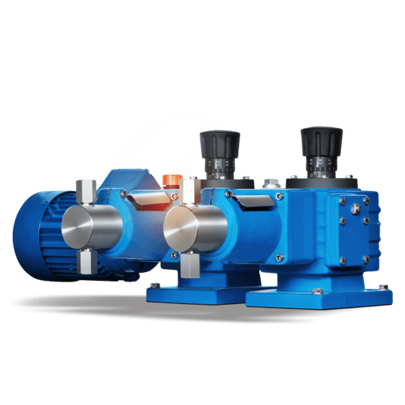

More DetailsLEWA ecoflow ® packed plunger metering pump

The LEWA ecoflow packed plunger metering pump is the robust, tried-and-tested metering pump for unproblematic fluids. It is available in a wide variety of models and used by well-known customers for various processes.

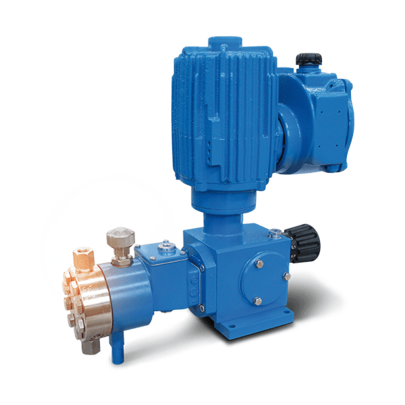

More DetailsLEWA MAH, MBH, MLM Micro-metering pumps

Metering pumps for very small flow rates. An especially cost-effective solution when fluid components must be metered proportionally to a variable reference value.

More DetailsLEWA FC laboratory pumps

Metering pumps for very small flow rates. The FC micro-metering pumps for pressures up to 400 bar were developed specifically for laboratories and test centers.

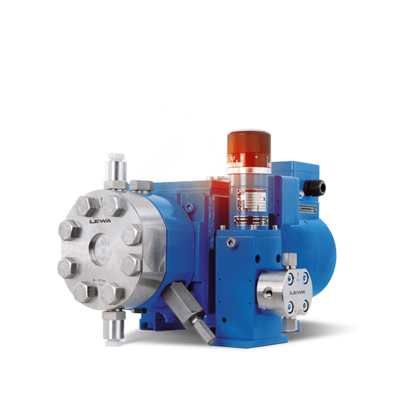

More DetailsLEWA Odorizing Systems

LEWA has been building odorizing systems for gases such as natural gas, oxygen, nitrogen, and carbon dioxide for more than 40 years. LEWA odorizing systems meter the odorant in question reliably, proportionally, and economically.

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsCustomer-Specific Metering Systems from LEWA

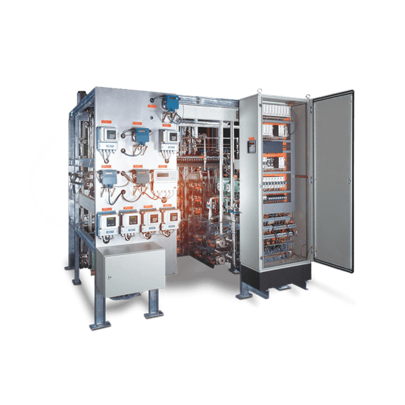

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More Details