Personal Care

Precise Results and High Quality with LEWA

Processes with strict quality and hygiene requirements, such as GMP or the production of personal care products without the use of preservatives, require the right equipment. We support you in the selection and the design of hygienic components and systems for manufacturing personal care products.

We create systems in accordance with your requirements and develop custom-made, integrated, efficient, and tested solutions that are designed for the durable, continuous production of your personal care products. To do so, we draw on our many years of experience in working with various fluids and materials and use our expertise in the areas of process and control technology.

LEWA Pumps and Systems for the Production of Personal Care Products

Our experts are on hand with help and advice and will work with you to develop custom systems and plants for manufacturing personal care products. You can rely on our many years of industry expertise in various processes.

| Typical Applications for LEWA Systems | Process examples |

|---|---|

| Conveyance | Transporting rheologically challenging fluids (e.g., surfactants) but also simple transfer tasks |

| Metering | Adding fragrances and colorants, etc. |

| Mixing/dispersion/homogenization | Proportionally mixing base materials and active materials, producing emulsions, and formulating end products |

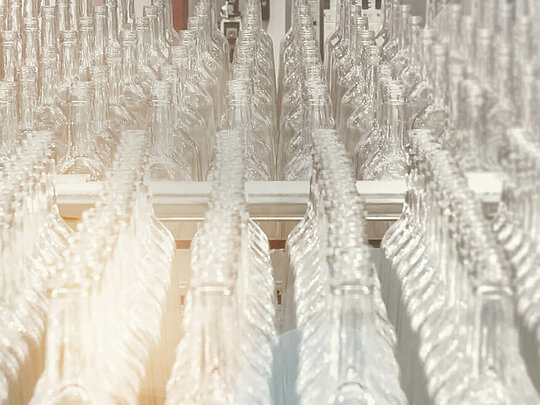

| Filling | Precisely filling containers |

| Tempering | Optimized procedure for continuous process (e.g., using heat recovery concepts) |

Our pumps and systems for the production of personal care products are used in various processes.

| Typical substances that we convey, meter, and process | Examples of end products |

|---|---|

| Solvents (Aqua), surfactants | Skin cleansers |

| Lipid components, nourishing ingredients | Skin care products |

| Titanium oxides | Dental and oral hygiene products |

| Colorants | Hair care products |

| UV filters | Cosmetic products with a special effect, e.g., sun protection products |

| Perfume oil | Perfumes and eau de toilette |

| Surfactants, moisturizers | Shaving products |

| Bulking agents, thickeners | Decorative cosmetics, body care products |

Advantages at a Glance

Minimization of unproductive times

Our systems are extremely reliable and low maintenance. Thus, you can get the maximum out of your production and avoid costly downtime.

Continuous processes

You can rely on the expertise of LEWA. We support you in the changeover from batch to continuous processes. Thus, your productivity is increased.

Economic solutions

We always deliver economic pumps, systems and units with minimized energy consumption, high efficiency, low maintenance and a long lifetime.

Flexible application

High variability in operation in terms of pressure, temperature, flow rate and fluid properties with high metering accuracy guarantee a wide range of applications.

Pilot plant for process optimization

You can rely on over 60 years of experience in the design of equipment and systems: In cooperation with you, we develop pilot plants to optimize your processes and procedures.

Easy to clean

An especially important advantage for pharmaceutical and food industry is that our systems can be quickly and easily cleaned with cleaning chemicals or hot steam.

International standards

LEWA pumps, systems and units are compliant with major international standards such as DVGW G280, WHG, PED, ISO 9001, ASME, ATEX and TA-Luft. Of course, you can also define your own standards.

Complete documentation

Receive supporting documents and certificates, including the operating instructions, as well as design and test details in different languages.

Maintenance and service

No matter if maintenance, spare parts or repair - our service technicians are well trained and available worldwide. Thus, we guarantee fast response and smooth operations.

Applications

Caustic soda production

At LEWA, find out about custom plants for producing and diluting different bases like caustic soda. Ask our experts for more information.

More DetailsExtraction with supercritical fluids

Processes with supercritical fluids in pharmaceutical, food and beverage industries. Ask our experts for more information!

More DetailsChemical metering in high-pressure cleaning systems

LEWA metering and process diaphragm pumps meet the specific demands for the production of melamine (trimerization of urea). Consult us!

More DetailsPharmaceutical spray drying

LEWA provides accurate and efficient diaphragm metering pumps for pharmaceutical spray drying. Consult us!

More DetailsDilution of surfactants

Dilution of surfactants such as sodium lauryl ether sulfate (SLES) with LEWA pumps during production of detergents.

More DetailsProduction of creams

With its metering systems and diaphragm pumps, LEWA offers the right solution for recipe-compliant production of creams.

More DetailsProducts

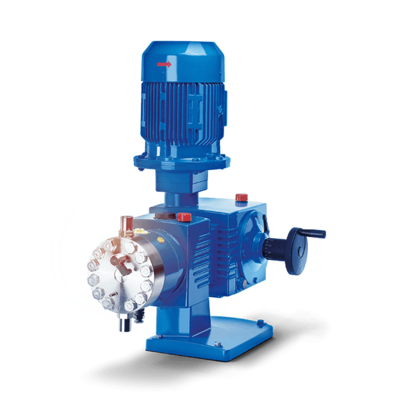

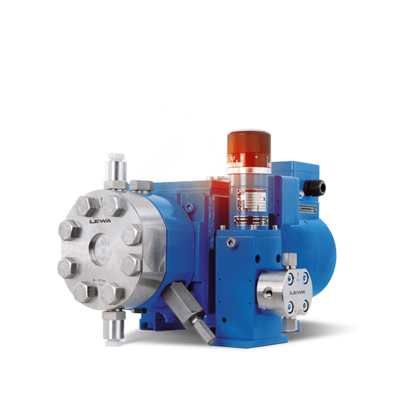

LEWA ecoflow® diaphragm metering pump

LEWA ecoflow is the innovative and universal metering pump with DPS diaphragm protection system in a tried-and-tested modular system. Suitable for numerous applications, the ecoflow is our real all-around talent, relied on by customers from all industries.

More DetailsLEWA ecoflow® sanitary/hygienic diaphragm metering pump

LEWA ecoflow is also available in sanitary/hygienic. The metering pump for hygienic applications has the same all-around capabilities and fulfills all specifications for pharmaceutical and food production.

More DetailsLEWA ecosmart® diaphragm metering pump

LEWA ecosmart is an innovative, compact and multiplexing diaphragm metering pump at a smart price. With it, we of course guarantee our renowned LEWA quality and offer you our expertise derived from 70 years in the market.

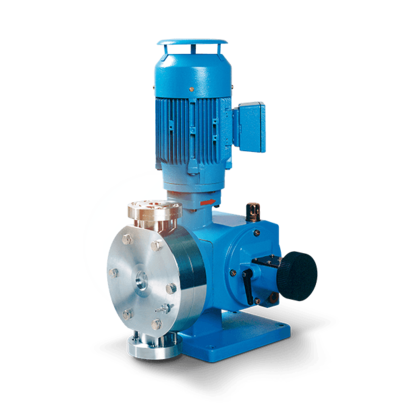

More DetailsLEWA ecodos® mechanical diaphragm metering pump

LEWA ecodos is an absolutely reliable, economical and highly adaptable metering pump, especially where diaphragm actuation is not wanted. Here, we also rely on our tried-and-tested modular system in designing the perfect pump for you.

More DetailsLEWA ecodos® sanitary/hygienic diaphragm metering pump

A sanitary/hygienic version is also available for the LEWA ecodos. Here, we meet all requirements for operation in pharmaceutical and food production.

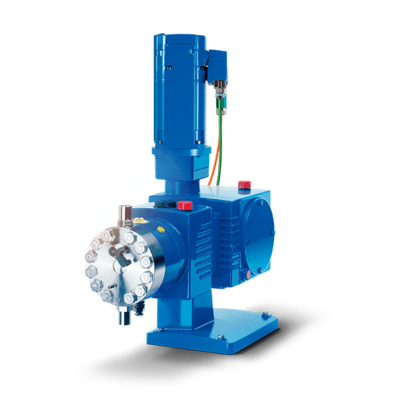

More DetailsLEWA intellidrive® diaphragm metering pump

Design the suction and discharge strokes of the metering pump to meet your specific requirements! With LEWA intellidrive technology, you can model pumping characteristics individually.

More DetailsLEWA MAH, MBH, MLM Micro-metering pumps

Metering pumps for very small flow rates. An especially cost-effective solution when fluid components must be metered proportionally to a variable reference value.

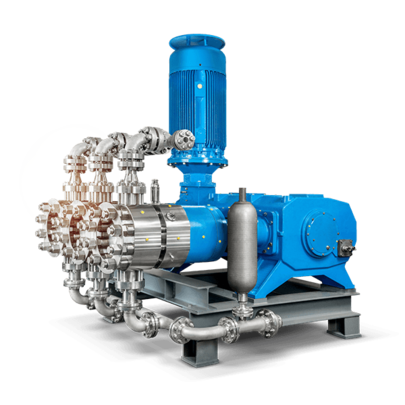

More DetailsLEWA triplex® process pumps for high-pressure processes

The LEWA triplex process diaphragm pump is among the world's most compact high-pressure pumps and can even be set up in the tightest spaces when space is at a premium. The power package has proven its strength in numerous high-pressure processes in a variety of industries. Oil and Gas icon Gas odor icon gray Refinery icon Petrochemicals icon Chemicals icon Plastics icon gray Cleaning icon Cosmetics icon Pharma icon Food icon Energy icon Other icon

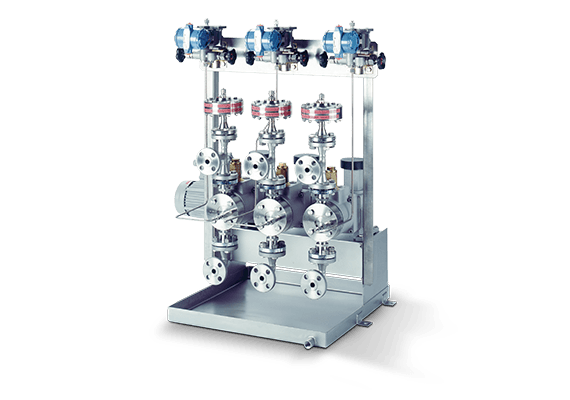

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

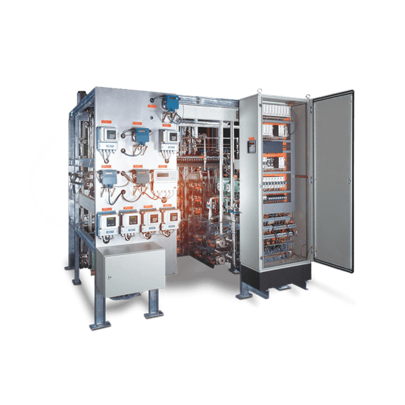

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

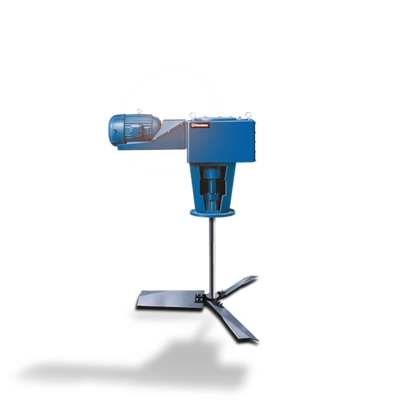

More DetailsChemineer Mixing technology

Chemineer agitators cover a wide range of products. From turbine agitators to impellers, these agitators can be used in almost any process that requires liquid or gas agitation.

More DetailsHNPM - Micro annular gear pump series HL

Micro annular gear pumps accomplish conventional micro fluidic tasks effectively and efficiently and open up new technological fields.

.

More Details